Thin Non-slip Rubber Gloves: Overall Enhance Protection and Efficiency in Work Scenarios

In many jobs, the safety and comfort of hands is an important link that cannot be ignored. An excellent protective gloves can not only ensure safety, but also significantly improve work efficiency. Today we will take an in-depth look at the " thin non-slip rubber gloves ", explore its unique charm and how to become an ideal choice for all kinds of workers.

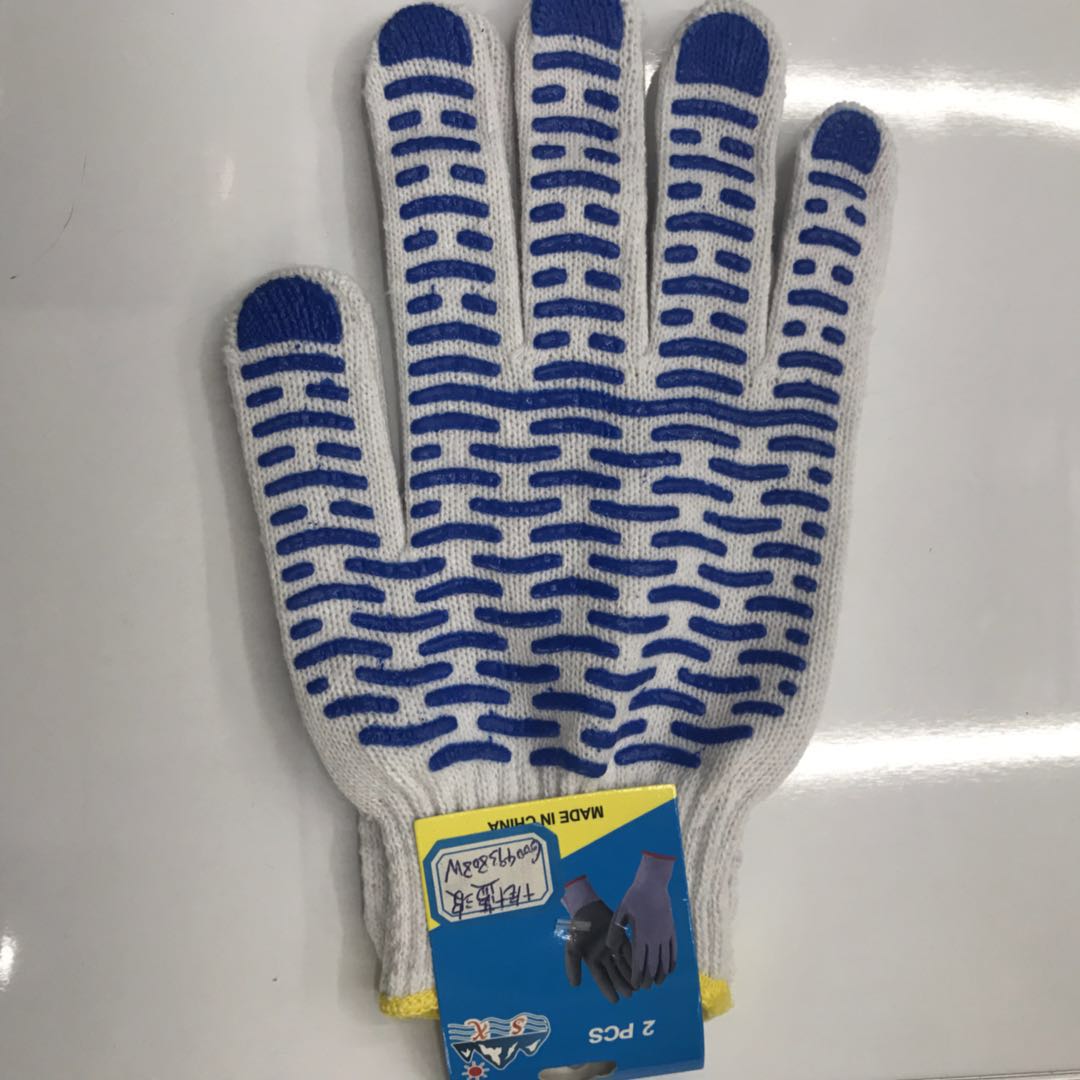

Starting from the details: The reason why thin non-slip rubber gloves are popular is inseparable from their excellent design concept. This glove is made of ultra-light material, which not only ensures sufficient strength, but also provides excellent feel and flexibility, which is very suitable for tasks requiring fine operation.

Material Analysis: Its core advantage comes from the application of high quality pure rubber components. Compared with some cheap alternatives on the market, this material has excellent water resistance and oil resistance, and has a strong grip, which can effectively prevent accidents caused by tools or objects falling off.

application scenario extension: is not limited to factory assembly lines or construction sites, such gloves are also suitable for gardening pruning, kitchen cooking and other fields. With their excellent performance, they break the traditional boundaries and meet more personalized needs.

highlights of humanized design: designers have fully considered the actual feelings of users and added elastic texture treatment to the knuckles, thus reducing the possibility of fatigue problems caused by long-term wearing. Special processes are used to enhance the friction coefficient in the palm area, making it easier to take heavy objects.

Durability test data: After several rounds of rigorous experimental verification, the average service life of this glove can reach hundreds of hours or more, far exceeding the average level of similar competitive brands. This achievement is due to the combination of advanced manufacturing technology and strict quality control processes.

Selection Guide: When faced with a wide variety of market options, please be sure to give priority to the following key factors-is the material composition clearly marked? Can the size and specification exactly fit the shape of your palm? In addition, you should pay attention to the introduction of specific functional attributes to accurately match your own use environment requirements.

Users' Voice: Many loyal customers have given high praise. "Since I started using these gloves, I don't have to worry about chemicals eroding the skin of my hands anymore!" A chemical plant employee said excitedly. Another technician in the car repair industry added: "It feels so good that there is no hindrance during the repair process."

Maintenance and care tips: Proper care methods help extend the product life cycle. It is recommended to remove the residual substances on the surface in time after each use, and store them in a cool and dry place to prevent deformation and aging.

Future trend outlook: With the continuous development and progress of science and technology, the next generation of protective gloves is expected to integrate smart sensor chips to achieve health monitoring and other functions, which will surely set off a new wave of revolution.

Industry comparison analysis: Although many new composite fiber products have emerged in the market to try to challenge the traditional position, but for now, rubber is still one of the undisputed best raw materials. Because it perfectly takes into account the economic benefits and comprehensive efficiency of the two indicators, can be called the king of cost-effective.